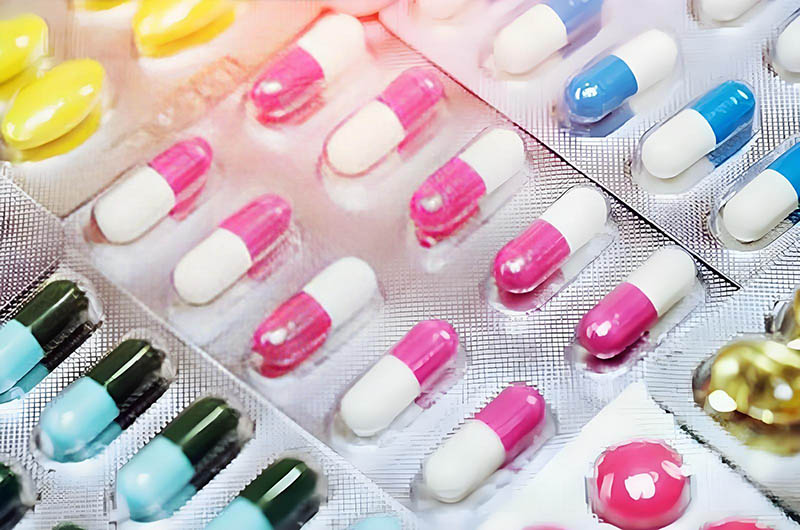

Alu-PVC Blister Packaging

Alu-PVC blister packaging is a widely used packaging form in the pharmaceutical industry. It consists of a combination of transparent PVC film and aluminum foil. This design aims to provide optimal protection for the medication, ensuring its stability and effectiveness during storage, transportation, and use.

Alu-PVC blister packaging is a commonly used pharmaceutical packaging solution that combines aluminum (Alu) and polyvinyl chloride (PVC) materials. It offers cost-effectiveness and moderate protective performance, making it suitable for products that do not require extremely high barrier protection.

ALU PVC blister packaging, as an important component of pharmaceutical packaging, holds a significant position in the global pharmaceutical packaging market due to its unique physical properties and cost advantages.

ALU PVC achieves a good balance between cost and performance, offering high cost-effectiveness. Although aluminum-aluminum (ALU-ALU) blister packaging is more expensive, it performs better in terms of barrier properties. For most conventional medications, ALU PVC provides sufficient protection and is a more economical choice.

PVC material dominates the global pharmaceutical blister packaging market due to its excellent thermoforming properties and moderate cost.

Alu-plastic blister packaging is a sealed packaging form composed of aluminum foil and plastic materials, mainly used for the individual sealed packaging of solid products such as pharmaceuticals and food.

Alu-PVC blister packaging is a packaging method widely used in the pharmaceutical industry for solid oral dosage forms such as tablets and capsules.

Alu-PVC Blister Packaging Composition

- PVC (Polyvinyl Chloride) Base Film: This transparent plastic film is thermoformed to create cavities for containing the product. It ensures the structural integrity of the product and provides clear visibility of the contents.

- Aluminum Foil Lid: This layer acts as a barrier against moisture, light, and oxygen, protecting the product from environmental factors that may affect its stability and efficacy. (The cover foil is heat-sealed to the PVC base layer to provide moisture and oxygen resistance.)

Alu-PVC Blister Packaging Material Characteristics and Selection

- Aluminum Foil: Must have high purity (complying with pharmaceutical hygiene standards), ductility (O temper), and resistance to stress concentration.

- Plastic Base Material: Must meet requirements for transparency, mechanical strength (such as tear resistance), and barrier properties. Polyvinyl chloride (PVC) is most commonly used due to its low cost and ease of processing, while composite materials (such as PVC/PVDC) can enhance barrier properties.

| Component | Material Type | Thickness Range | Functional Description |

| Outer Aluminum Foil | 8011, 8021, 8079 Aluminum Alloys | 0.04 ~ 0.075 mm | Provides high barrier properties (moisture-proof, light-blocking, oxygen resistance) and good sealing performance to protect the stability and safety of the contents |

| Inner Plastic Base Material | PVC (Polyvinyl Chloride), PET, PP | 25 ~ 35 mm (commonly used) | Provides mechanical support with good plasticity for blister forming, ensuring packaging shape and product fixation |

| Adhesive Layer | Specialized Adhesive or Heat-Sealing Coating | / (Very thin, not commonly measured separately) | Achieves strong bonding between the aluminum foil and plastic base material, ensuring sealing strength and preventing delamination |

ALU PVC blister products are usually composed of multiple layers of composite materials, with the most common structure being the OPA/Alu/PVC three-layer composite. Among them:

- OPA layer (Oriented Polyamide): Serves as a middle isolation layer to prevent direct contact between the drug and the aluminum foil, avoiding potential reactions or interactions.

- Aluminum foil layer: Provides excellent barrier properties, completely blocking moisture, oxygen, and light to protect the drug from moisture degradation and oxidation.

- PVC layer: Acts as the inner layer in direct contact with the medication, offering good thermoformability and transparency.

Common specifications of ALU PVC composite film structures include:

| Structure | Weight per square meter | Applicable range |

| OPA25/Alu45/PVC60 | 240 | Smaller blisters (e.g., tablets) |

| OPA25/Alu60/PVC60 | 280 | Larger blisters (e.g., capsules) |

Alu-PVC Blister Packaging Aluminum Foil Alloy Selection

The most commonly used aluminum foil alloys in Alu-PVC blister packaging are 8011, 8021, and 1235. These alloys provide good sealing and corrosion resistance, making them suitable for various types of drug packaging. Choosing the right aluminum foil alloy, along with its thickness and surface treatment, can effectively protect the drugs and ensure their quality and safety during transport and storage.

- 8011 Aluminum Alloy: Widely used in blister packaging for pharmaceuticals, food, and health products, especially suitable for packaging with higher strength requirements.

- 8021 Aluminum Alloy: Mainly used for packaging drugs that are particularly sensitive to moisture, oxygen, and light, such as some high-efficiency drugs, hormones, etc.

| Aluminum Alloy Type | Main Components | Features | Advantages | Common Applications |

| 8011 Aluminum Alloy | Aluminum, with iron and silicon | Good strength and corrosion resistance, suitable for complex packaging applications. | Higher strength, suitable for packaging requiring greater mechanical strength, maintaining the integrity of the packaging. | Pharmaceuticals, food, health product packaging. |

| 8021 Aluminum Alloy | Aluminum, with a small amount of magnesium and silicon | Higher mechanical strength, strong resistance to moisture and light. | Enhanced protective properties, suitable for packaging moisture and oxygen-sensitive drugs. | High-efficiency drugs, hormone drugs packaging. |

Alu-PVC Blister Packaging Aluminum Foil Thickness Selection

| Aluminum Foil Thickness | Features | Suitable For |

| 20μm (Thin Aluminum Foil) | Provides higher transparency and good formability. | Suitable for light packaging, such as regular pharmaceuticals, health products, nutritional supplements. |

| 40μm (Thick Aluminum Foil) | Offers stronger mechanical strength and better barrier performance. | Suitable for drug packaging with higher environmental protection requirements, such as moisture and oxygen-sensitive drugs. |

| 50μm (Thicker Aluminum Foil) | Provides even stronger mechanical strength, tear resistance, and superior barrier performance. | Suitable for drugs with high protection requirements, commonly used for high-efficiency drugs and hormone drug packaging. |

Maximum width: Typically 225mm, up to 270mm on some equipment

Thickness range:

PVC film: 0.15–0.5mm

Aluminum foil: 0.02–0.035mm

Total thickness: Approximately 0.23–0.56mm

Maximum forming depth: PVC can reach up to 28mm

Minimum/Maximum area: 210×25mm to 210×135mm

Alu-PVC Blister Packaging Aluminum Foil Layer Surface Treatment

| Treatment Method | Features | Effect and Application |

| Coating Treatment | The aluminum foil surface may be coated with anti-corrosion or gloss-enhancing coatings. | Improves the durability, corrosion resistance, and enhances the appearance of the packaging, suitable for long-term storage and transportation. |

| Printing Treatment | The aluminum foil surface can be printed with drug information, brand logos, or other necessary labels. | Provides labeling, product instructions, and brand identification on the packaging, ensuring accurate communication of drug information. |

Physical Performance Parameters

Tensile strength:

PVC film: ≥450kg/cm² (approx. 44.1MPa)

Aluminum foil: ≥180MPa, elongation ≥2.5%

Al/PVC heat seal strength: ≥7.8N/15mm

NY/Al strength: ≥10.0N/15mm

Density: 1.35–1.4g/cm³

Light transmittance: Transparent PVC layer >88% or 90%

Haze: ≤3%

Barrier Performance Parameters

Oxygen transmission rate: PVC sheets using co-extrusion composite technology can achieve an oxygen transmission rate below 5cc/m²·day

Water vapor transmission rate: ≤5g/m²·24h

Air barrier: Excellent air barrier performance effectively prevents drug oxidation

Common Specifications and Applications

| Product Type | Thickness Range | Main Features | Typical Applications |

| Standard Type | 0.2–0.3mm | Medium strength, good transparency | Regular tablets, capsules |

| Thickened Type | 0.3–0.5mm | High strength, excellent protection performance | Large capsules, fragile medicines |

| High Transparency Type | 0.15–0.25mm | Light transmittance ≥90%, haze ≤3% | Medications requiring high visibility |

| Anti-static Type | 0.2–0.4mm | Surface resistance 1×10⁵–1×10¹¹Ω | Electronic medical devices, sensitive electronic components |

Alu-PVC Blister Packaging Features

Visibility and Display

High Transparency

The transparent PVC layer can achieve a light transmittance of up to 92%. Its excellent transparency allows the packaged medicine to be clearly visible, facilitating identification and verification.

Clear Visual Effect

With low haze (≤3%), the visual appearance is clear, with no noticeable water ripples or defects, enhancing the product's premium look.

Optimized Optical Performance

Refractive index is controlled within the range of 1.53±0.01, and birefringence is low (<3×10⁻⁵), reducing optical distortion.

Protection and Barrier Properties

Excellent Barrier Properties

The aluminum foil layer almost completely blocks water vapor, oxygen, and light. PVC sheets made using co-extrusion technology can achieve oxygen transmission rates below 5cc/m²·day.

Physical Protection

The PVC layer offers high toughness and impact resistance, along with good puncture resistance to prevent damage from sharp objects.

Chemical Stability

Good resistance to chemical corrosion, can withstand various pharmaceutical ingredients. The OPA layer prevents direct contact between drugs and aluminum foil.

Usability and Functionality

Convenient Opening Design

Easy-tear notches or weakened lines can be designed for convenient patient access, with moderate opening force to ensure both seal integrity and ease of use.

Accurate Dose Management

Single-dose or multi-dose packaging can be designed for dose management. Blister design allows patients to access medication by dose.

Multi-Functional Design

Desiccants or oxygen absorbers can be integrated to further enhance protection. Observation windows or marking areas can also be added for labeling purposes.

Processing Adaptability and Compatibility

Excellent Thermoforming Performance

PVC material has excellent thermoforming properties, can be molded into various complex shapes, with a wide forming temperature range and easy processing.

Wide Heat-Sealing Compatibility

Compatible with various aluminum foil materials for heat sealing, with a wide range of sealing temperatures and high sealing strength.

Printability and Decorative Properties

The PVC surface can undergo various printing and decorative treatments. It offers strong ink adhesion with clear and long-lasting print results.

Environmental Adaptability and Stability

Temperature Adaptability

Maintains stable performance within the temperature range of -20°C to 50°C, suitable for storage and transportation under various climate conditions.

Humidity Stability

Excellent moisture resistance with low water vapor transmission rate, maintaining good physical properties in high-humidity environments.

Long-Term Storage Stability

High material stability, not prone to aging or deterioration. The aluminum foil layer provides long-term light shielding and oxygen barrier.

Advantages of Alu-PVC Blister Packaging

- Safety: Individually sealed units reduce the risk of contamination and are only opened at the time of use.

- Convenience: Compact blister sizes (e.g., 35mm×10mm to 78mm×5mm) make them easy to carry and allow for precise dosage control.

- Versatility: Suitable for various solid dosage forms such as tablets, capsules, and suppositories, and supports customized arrangements (each blister can hold 1~3 units).

- Protection: The aluminum foil effectively blocks moisture, light, and oxygen, preserving product integrity.

- Visibility: The transparent PVC film allows consumers to view the product, aiding in identification and enhancing consumer confidence.

- Cost-Effectiveness: Compared to other packaging methods, Alu-PVC blister packaging is relatively inexpensive and suitable for mass production.

- Customization: The packaging can be tailored in terms of size, shape, and design to meet specific product requirements.

- Flexibility: PVC can be molded into various shapes and sizes to accommodate different product geometries.

- Moderate Barrier: The aluminum lid provides reasonable moisture and light protection, though it is less robust than Alu-Alu packaging.

Applications of Alu-PVC Blister Packaging

Alu-PVC blister packaging is primarily used in the pharmaceutical industry:

- Pharmaceuticals: Used for packaging tablets and capsules, especially non-light-sensitive tablets (e.g., paracetamol) and capsules that do not require extremely high barrier protection.

- Consumer Goods: Due to its durability and transparency, also used for batteries, cosmetics, and small electronic products.

- Supplements: Non-light-sensitive vitamins and probiotics.

Pharmaceutical and Healthcare Industry

This is the most prominent application field for aluminum-PVC blister packaging, as it protects drugs from moisture, oxygen, light, and contamination while ensuring accurate dosing.

Solid Dosage Forms:

Tablets and capsules: The PVC layer forms transparent, rigid blisters for holding single doses, making the medicine clearly visible. The aluminum layer (typically a thin foil) serves as a seal to provide airtight and moisture-proof barriers.

Lozenges, chewable tablets, and effervescent tablets: Prevent moisture absorption, which could otherwise affect texture or efficacy.

Controlled-Release Medications:

Blister packaging maintains the integrity of sustained or enteric-release tablets, preventing premature disintegration due to environmental factors.

Pediatric and Geriatric Medication:

Individual blister packaging reduces the risk of accidental overdose. Packaging can feature child-resistant (CR) or senior-friendly designs (such as easy-peel tabs).

Vaccines and Medical Devices:

Small medical items such as syringes, needles, or vaccine vials (micro-blister packs) often use aluminum-PVC packaging to ensure sterility and prevent tampering.

Food and Confectionery Industry

Aluminum-PVC blister packaging is suitable for portion control, shelf-stable, or fragile food items, offering both visibility (PVC) and extended shelf life (aluminum).

Confectionery:

Chocolate, mints, and hard candies: PVC blisters highlight product appearance, while aluminum seals provide moisture resistance and freshness.

Gummies or chewy snacks: Barrier against humidity prevents sticking and maintains texture.

Snacks and Convenience Foods:

Single-serve nuts, dried fruits, or oatmeal: Freshness and portability.

Seasoning or spice packets: Prevent caking due to moisture exposure.

Specialty Foods:

Dietary supplements (e.g., vitamins, probiotics) often use aluminum-PVC blisters to preserve potency by blocking oxygen and light.

Cosmetics and Personal Care

The transparency and protection make this packaging ideal for small, high-value beauty products.

Cosmetics:

Eyeshadow palettes, blush, or pressed powder: PVC blisters showcase color and texture, while the aluminum backing provides structure and prevents moisture absorption.

Lip balm, solid perfume, or hair wax: Require protection from heat and humidity to avoid melting or degradation.

Personal Care Products:

Single-use skincare samples (e.g., serums, creams) or travel-size toiletries: Blister packaging ensures sterility and portability.

Electronics and Small Hardware

Aluminum-PVC blister packaging provides safe and organized storage for small precision components, with both protection and visibility.

Electronics:

Batteries, microchips, connectors, or small sensors: Dust-proof, moisture-proof, anti-static (using anti-static PVC materials), while allowing customers to inspect the product.

Hardware Tools:

Screws, nails, bolts, or small DIY parts: Blister packaging aids identification and prevents loss.

Toys and Crafts:

Small toy parts, beads, or craft items: Blister packs keep sets complete and neatly display the contents.

Veterinary Medicine

Similar to human pharmaceuticals, aluminum-PVC blister packaging is used for veterinary drugs to ensure accurate dosing and protection from environmental factors.

Pet supplements: Chewable or oral medicines for dogs, cats, or livestock benefit from moisture resistance to maintain palatability and efficacy.

Key Advantages Driving These Applications

Barrier Properties: Aluminum blocks oxygen, moisture, and light, while PVC offers rigidity and transparency.

Tamper-Evidence: Aluminum seals are easy to inspect for tampering, which is essential for pharmaceuticals and food.

Portability: Individual blister packs make products easy to carry (e.g., travel toiletries, on-the-go medications).

Customization: Blisters can be molded to fit various product sizes, and aluminum layers can be printed for branding.

The versatility of aluminum-PVC blister packaging—combining protection, visibility, and practicality—makes it indispensable in industries where product integrity, safety, and appearance are crucial.

Key Production Steps of Alu-PVC Blister Packaging

The production of Alu-PVC blister packs involves several critical steps:

- Thermoforming: The PVC film is heated and formed into cavities that match the shape and size of the product.

- Filling: The product (such as tablets or capsules) is placed into the formed cavities.

- Sealing: The aluminum foil is placed over the filled cavities and sealed, typically using heat and pressure to ensure a secure seal.

- Cutting and Packaging: The sealed blister strips are cut into individual packages, ready for distribution.

Comparison with Alu-Alu Packaging

| Aspect | Alu-PVC | Alu-Alu |

| Cost | Lower (PVC is economical) | 50% higher due to aluminum layers |

| Barrier | Moderate moisture/oxygen resistance | Near-complete barrier |

| Visibility | Transparent PVC allows inspection | Opaque, no visibility |

| Production Speed | Faster (thermoforming) | Slower (cold forming) |

Limitations of Alu-PVC Blister Packaging

- Barrier Weakness: Compared to Alu-Alu packaging, PVC has lower moisture and oxygen barrier properties, making it unsuitable for highly sensitive medications such as effervescent tablets.

- Environmental Issues: PVC is non-biodegradable, and its composite structure with aluminum poses challenges for recycling.

- Heat Sensitivity: The permeability of PVC increases with temperature, which may affect product stability in hot climates.

Alu-PVC blister packaging is an ideal choice for cost-sensitive applications that require moderate protection and visual appeal. While it is not as impermeable as Alu-Alu blister packaging, its versatility and affordability make it a mainstream option in the pharmaceutical and consumer goods sectors.

Alu-PVC Blister Packaging Common Issues and Solutions

Poor Heat Sealing and Its Solutions

Poor heat sealing is one of the most common problems in ALU PVC blister packaging production:

| Problem Phenomenon | Cause Analysis | Solution |

| Weak or partially unsealed heat sealing | Insufficient sealing temperature, inadequate pressure, too short sealing time, contamination on the sealing surface | Increase sealing temperature, apply more pressure, extend sealing time, clean sealing surface |

| Insufficient sealing strength | Sealing temperature too low, sealing time too short, improper material selection | Adjust sealing temperature and time, select suitable heat seal coating materials, increase sealing area |

| Bubbles appear after sealing | Sealing speed too fast, high moisture content in materials, uneven sealing temperature | Reduce sealing speed, pre-dry the materials, adjust temperature distribution |

| Uneven heat-seal edges | Worn sealing die, uneven pressure, inconsistent material thickness | Replace the die, adjust pressure distribution, check material thickness uniformity |

Forming Defects and Solutions

| Problem Phenomenon | Cause Analysis | Solution |

| Incomplete forming or inadequate vacuum forming | Insufficient vacuum, inadequate temperature, poor mold design, poor material flowability | Check the vacuum system, increase heating temperature, optimize mold design, choose materials with better flowability |

| Uneven forming thickness | Uneven heating, uneven mold temperature distribution, inconsistent material thickness | Adjust heating system, optimize mold cooling system, use uniformly thick materials |

| Surface defects after forming | Impurities on material surface, rough mold surface, dust contamination during forming | Clean material surface, polish mold surface, improve cleanliness of production environment |

| Shrinkage or deformation after forming | Insufficient cooling, high material shrinkage rate, premature demolding | Extend cooling time, select materials with lower shrinkage, adjust demolding time |

Product Quality Issues and Solutions

| Problem Phenomenon | Cause Analysis | Solution |

| Insufficient transparency or haziness | Improper material selection, overly high processing temperature, too rapid cooling | Choose high-transparency materials, optimize processing temperature, adjust cooling rate |

| Surface scratches or damage | Friction during production, impact during transport, improper packaging | Improve surface smoothness of production equipment, optimize transport packaging, add protective measures |

| Large dimensional deviations | Low mold precision, material shrinkage variation, temperature fluctuation during processing | Improve mold precision, control material batch consistency, stabilize processing temperature |

| Odor or solvent residue | Residual solvents in ink or coatings, odor in the raw material, decomposition due to overheating | Use low-residue inks and coatings, pre-dry materials, control processing temperature |

Packaging Performance Issues and Solutions

| Problem Phenomenon | Cause Analysis | Solution |

| Insufficient barrier performance | Improper material selection, poor heat sealing, insufficient material thickness | Choose high-barrier materials, optimize heat sealing process, increase material thickness |

| Opening force too high or too low | Heat seal strength too high or too low, unreasonable opening structure design | Adjust heat sealing parameters, optimize opening structure design, add tear lines or weakened areas |

| Inadequate seal integrity | Poor heat sealing, material defects, impact during transportation | Strengthen heat seal quality control, enforce strict material inspection, optimize transport packaging |

| Drug compatibility issues | Interaction between packaging materials and drug ingredients | Conduct compatibility tests between packaging materials and drugs, choose appropriate barrier layer materials |