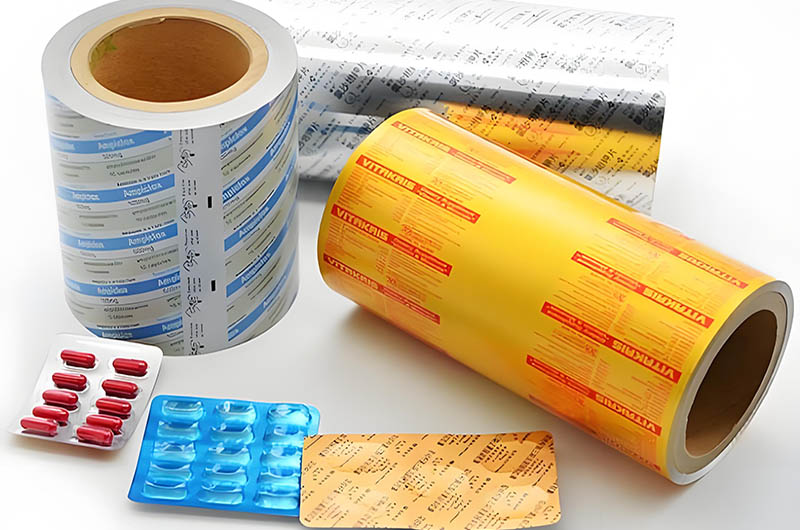

Aluminium Blister Foil

What is Aluminium Blister Foil?

Aluminium blister foil is a thin sheet of aluminum alloy used in blister packaging (typically 20–30 microns thick, usually made from alloys such as 8011 and 8021). It offers excellent barrier properties against moisture, gases, and light, has good heat-sealing performance, allows for printing of product information, and possesses sufficient toughness. It is widely used in the packaging of pharmaceuticals, food, and cosmetics to protect the contents, and is non-toxic and recyclable.

Aluminium Blister Foil Specifications

The thickness of aluminium blister foil is one of the key factors determining its performance in application. Different application scenarios have varying requirements for foil thickness. Aluminium blister foil thickness is usually expressed in microns (μm) or millimeters (mm), with common thicknesses ranging from 18μm to 100μm (i.e., 0.018mm to 0.100mm).

| Item | Specification Description |

| Alloy and Temper | Pharmaceutical-grade aluminium alloys: 8011, 8021, 8079 |

| Temper: | |

| O temper (soft): offers greater ductility and enhances child-resistant features | |

| H18 temper (hard): commonly used in Europe, thickness usually 25–30μm, facilitates easy push-through for medication access | |

| Thickness Range | Standard thickness: 20–30 microns (0.02–0.03 mm) |

| Customizable thickness: 0.015–0.08 mm | |

| Coating Type | Heat Seal Lacquer: |

| Suitable for heat sealing with PVC, PVDC, and other blister materials | |

| Coating weight: 4–8 GSM, ensuring excellent sealing performance | |

| Printing layer and coating surface treatment: | |

| One side printable for medication information (e.g., expiration date) | |

| Matte surface specially treated to enhance adhesion | |

| Compatibility with Blister Materials | Compatible with commonly used plastic blister materials such as PVC, PVDC, and PP |

| Packaging Feature Supplement | H18 hard foil is suitable for “easy push-through” dispensing |

| O temper soft foil supports child-resistant packaging design |

Thickness options vary:

- Ultra-light foil: thickness 0.006-0.007mm, mainly used for weight-sensitive packaging

- Light foil: thickness 0.008-0.012mm, suitable for general pharmaceutical and food packaging

- Standard foil: thickness 0.018-0.030mm, the most commonly used thickness range for blister packaging materials

- Medium foil: thickness 0.030-0.050mm, suitable for packaging applications requiring higher strength

- Heavy foil: thickness 0.050-0.100mm, mainly used for special packaging requirements or structural support

In the pharmaceutical packaging field, 8021 aluminum foil (also known as blister foil) typically has a thickness between 0.04–0.065mm. This thickness range provides good barrier performance and mechanical strength. PTP aluminum foil (8011 aluminum foil) is relatively thinner, generally ranging from 0.016–0.04mm.

| Type of Aluminium Foil | Alloy & Temper | Thickness Range (mm) | Main Application Area |

| PTP Aluminum Foil | 8011-H18 | 0.016-0.04 | Standard pharmaceutical blister packaging |

| Blister Aluminium Foil | 8021-O | 0.04-0.065 | High-end pharmaceutical packaging |

| Cold-Forming Foil | 8021-O, 8079-O | 0.025-0.08 | High-seal pharmaceutical packaging |

| Tropical Blister Foil (Base Material) | 8021-O, 8079-O | 0.04-0.075 | Pharmaceutical packaging for tropical regions |

| Pure Aluminum Foil | Pure aluminum | 0.02-0.03 | Food packaging, general industrial use |

Main Types of Aluminium Blister Foil

Aluminium blister foil can be categorized into various types based on alloy composition, production process, and application area. Each type has its unique performance characteristics and suitable applications.

Classification by Alloy Composition

8011 Blister Aluminum Foil

- The most commonly used material for pharmaceutical aluminum foil

- Contains a higher silicon content, as well as manganese and iron

- Offers high strength and corrosion resistance

- Typically processed in H18 temper

- Surface is coated for use in PTP pharmaceutical aluminum foil

8021 Blister Aluminum Foil

- Also known as aluminum blister foil

- Mainly made from 8021-O temper aluminum foil

- Primary material for cold-forming pharmaceutical foil

- Iron content ranges from 1.2% to 1.7%

- Exhibits excellent properties, especially ultra-high barrier performance

8079 Blister Aluminum Foil

- Common material for cold-forming pharmaceutical foil

- Silicon content ranges from 0.05% to 0.30%

- Iron content ranges from 0.7% to 1.3%

- Along with 8021 aluminum foil, it is a major raw material supplier for cold-form pharmaceutical aluminum foil in domestic and international pharmaceutical packaging industries

Pure Aluminum Foil

- High-purity aluminum foil (e.g., grades 1100, 1200)

- Mainly used in general packaging fields with low corrosion resistance requirements

- Typically thin, with thickness between 0.02–0.03mm

Classification by Production Process

Soft (O Temper) Blister Aluminum Foil

- Fully annealed

- Has good flexibility and ductility

- Mainly used for high-end pharmaceutical packaging in cold-forming applications

- Surface should be oil-free and pass brushing water test at Grade B or better

Hard (H18 Temper) Blister Aluminum Foil

- Processed through work hardening

- Offers higher hardness

- Mainly used for PTP pharmaceutical aluminum foil

- H18 foil with coating has good printing and heat-sealing properties

Coated Blister Aluminum Foil

- Coated with one or more functional layers on the foil surface

- Includes heat-sealing layer, printing layer, or protective layer

- Coated foil is usually processed through specialized equipment for printing, coating, and drying

Laminated Blister Aluminum Foil

- Composed by laminating aluminum foil with other materials (such as plastic films, paper, etc.) using adhesive

- Multi-layer structured material

- Provides comprehensive performance such as higher barrier properties, heat sealability, and mechanical strength

Classification by Application Field

| Type | Alloy/Temper | Main Features | Typical Application |

| PTP Blister Aluminum Foil | 8011-H18 | High strength, good corrosion resistance, excellent printability | Standard pharmaceutical blister packaging |

| Cold-Form Pharmaceutical Blister Foil | 8021-O | Ultra-high barrier properties, good cold-forming performance | High-end pharmaceutical packaging, moisture-proof and light-blocking packaging |

| Tropical Blister Foil | 8021-O, 8079-O | Multi-layer composite structure, excellent moisture resistance | Pharmaceutical packaging for tropical regions, high humidity environment packaging |

| Blister Aluminum Foil for Food Packaging | Pure aluminum or 8011 | Non-toxic, odorless, good heat sealability | Blister packaging for food and health products |

| Electronic Component Packaging Foil | Various alloys | Anti-static, good shielding properties | Packaging of electronic components, lithium batteries |

Types of Aluminium Blister Packaging Structures

Aluminium blister packaging is a protective packaging form widely used in pharmaceuticals, food, and consumer goods. It consists of aluminum foil and rigid plastic or aluminum-plastic composite materials, sealed through thermoforming or cold-forming processes. Based on structure and material composition, aluminium blister packaging can be divided into the following types:

| Packaging Type | Main Structure | Material Composition | Features | Application Field |

| Alu-Plastic Type (PTP) | Rigid plastic film + aluminum foil | PVC/PVDC + aluminum foil | Low cost, fast production, convenient to use | Standard pharmaceuticals, food, health products |

| Alu-Plastic-Alu Type (Tropical Type) | Rigid plastic film + aluminum-plastic composite film | PVC + NY/AL/VC | Good barrier, moisture-proof and light-blocking | Pharmaceuticals in tropical regions, high-humidity environment products |

| Alu-Alu Type (Cold Forming) | Full aluminum structure | Aluminum foil / heat seal layer | Ultra-high barrier, cold forming | High-end pharmaceuticals, products with high barrier demands |

| Double Aluminum Packaging | Aluminum foil - product - aluminum foil | Aluminum foil / composite material / aluminum foil | Completely light-proof, ultra-high barrier | Photosensitive, highly sensitive products |

| Aclar® Composite Packaging | Aclar®/PVC + aluminum foil | Aclar®/PVC + aluminum foil | Excellent moisture resistance, chemical stability | High-spec pharmaceutical, specialty products |

Alu-Plastic Blister Packaging (PTP)

PTP (Press Through Packaging) is the most common type of blister packaging, mainly composed of rigid plastic sheet (such as PVC, PVDC, or composite materials) and aluminum foil as the lidding material. The plastic sheet forms cavities through thermoforming to hold the product, and the aluminum foil is sealed on top using heat or adhesives.

Alu-Plastic-Alu Blister Packaging (Tropical Type)

Tropical-type blister aluminum is a combination of thermoformed plastic blister and cold-formed composite aluminum, mainly used for pharmaceutical packaging in tropical regions or environments with high moisture demands. It is usually composed of nylon, aluminum, and adhesive, laminated together under specific temperature and pressure using specialized equipment.

Alu-Alu Blister Packaging (Cold Forming Type)

Alu-Alu blister packaging, also known as cold forming or Alu-Alu packaging, is a full aluminum structure with extremely high barrier properties. Using specially designed molds, the aluminum foil is cold-formed at room temperature to create cavities. Since no heating is required, the process is called "cold forming."

Double Aluminum Packaging

Double aluminum packaging is a special form of blister packaging where the product is sealed between composite materials. The composite is a multi-layer structure including at least two aluminum foil layers, and is typically opaque so the product cannot be seen from the outside. This packaging provides excellent light-blocking and barrier properties, effectively protecting products sensitive to light, moisture, and oxygen.

Material Properties of Aluminium Blister Foil

As a high-performance packaging material, aluminium blister foil possesses various excellent physical and chemical properties, which directly determine its suitability and advantages in packaging applications.

| Property Category | Specific Property | Impact on Packaging Application |

| Physical Properties | Lightweight, good ductility | Easy to carry and transport, can be processed into extremely thin foil |

| Adjustable hardness and strength | Suitable temper can be selected according to application needs | |

| Chemical Properties | Non-toxic, odorless, inert | Suitable for direct contact with sensitive products like food and pharmaceuticals |

| Good corrosion resistance | Protects products from environmental impact | |

| Barrier Properties | Completely blocks gas, water, and light | Protects products from oxygen, moisture, and light damage |

| High flavor retention | Preserves the original taste and aroma of the product |

Physical Properties

- Density and Weight: The density of aluminum is approximately 2.7g/cm³, making it a lightweight metal. Aluminum blister foil is very light, easy to carry and transport, while offering sufficient strength.

- Thickness and Ductility: Aluminum foil has excellent ductility and can be rolled into extremely thin sheets, typically ranging from 10μm to 200μm. The thickness of aluminum blister foil generally falls between 18μm and 100μm.

- Surface Characteristics: The surface of aluminum foil can be either bright or matte, depending on the production process and post-treatment. Double-sided bright aluminum foil is rolled as a single sheet, with both sides in contact with the rolls, resulting in excellent surface quality.

- Hardness and Strength: The hardness and strength of aluminum blister foil can be adjusted through alloy composition and processing conditions. Soft blister foil (e.g., O temper) offers good flexibility and ductility, while hard foil (e.g., H18 temper) provides higher hardness and strength.

- Thermal Properties: Aluminum has good thermal conductivity and stability, and can withstand a range of temperature changes. Aluminum foil has excellent thermal stability, which supports bonding processes and enables high-speed automated production.

Chemical Properties

- Corrosion Resistance: Aluminum easily forms a dense layer of aluminum oxide film in air, providing excellent corrosion resistance. 8011 aluminum foil, which has higher silicon content and includes manganese and iron, offers greater strength and corrosion resistance.

- Chemical Stability: Aluminum foil maintains chemical stability under normal usage conditions and is unlikely to react with the packaged contents. This makes it particularly suitable for packaging sensitive products such as pharmaceuticals and food.

- Non-Toxicity: Aluminum blister foil is non-toxic, tasteless, and harmless to human health. This property allows it to be safely used for long-term contact with food products.

- Inertness: Aluminum foil exhibits good chemical inertness and is resistant to corrosion by most chemicals, making it suitable for packaging a wide range of products.

Barrier Properties

- Gas Barrier: Aluminum foil’s dense metallic crystal structure allows it to completely block all gases, including oxygen and carbon dioxide.

- Moisture Barrier: Aluminum foil provides excellent resistance to water vapor, effectively preventing product deterioration caused by moisture.

- Light Barrier: Aluminum foil offers outstanding light-blocking properties, fully shielding against ultraviolet and visible light to protect light-sensitive products.

- Flavor Retention: Aluminum foil has high flavor retention ability, effectively preserving the original taste and aroma of the product.

Advantages of Aluminum Blister Foil

As a high-performance packaging material, aluminum blister foil is widely used in the pharmaceutical, food, and electronics industries due to its unique advantages and characteristics.

| Advantage Category | Specific Advantage | Impact on Application |

| Protective Performance | High barrier, moisture and water resistance | Extends product shelf life, reduces product loss |

| Anti-oxidation, light protection | Maintains product quality and efficacy | |

| Physical and Chemical Stability | Heat resistance, low-temperature adaptability | Suitable for products under various environmental conditions |

| Processing and Usability | Easy to process, suitable for high-speed production | Ideal for large-scale industrial production, enhances efficiency |

| Economic and Environmental Benefits | Cost-effective, lightweight | Reduces overall packaging and transportation costs |

Excellent Protective Properties

- High barrier: completely blocks oxygen, water vapor, light, and microorganisms

- Moisture and water resistance: effectively prevents product deterioration due to moisture

- Anti-oxidation: prevents oxidation and spoilage, extends shelf life

- Light protection: protects light-sensitive products

- Anti-contamination: prevents contamination during handling and use

Good Physical and Chemical Stability

- Heat resistance: can withstand high-temperature environments

- Low-temperature adaptability: retains flexibility and strength at low temperatures

- Chemical stability: resistant to most chemicals

- Corrosion resistance: forms a dense aluminum oxide film on the surface

- High stability: resists aging, deterioration, or deformation

Convenient Usability and Processing

- Easy to process, excellent ductility and formability

- Lightweight and compact, easy to carry

- User-friendly design for easy opening and access

- Compatible with high-speed automated production

- Printable: surface suitable for printing and coating

Economic and Environmental Benefits

- High cost-efficiency, reduces product loss and waste

- Lightweight: reduces packaging and transportation weight

- Space-saving: compact design saves storage and shipping space

- Recyclability: highly recyclable with low energy consumption

- Environmentally friendly: minimal environmental impact during production and use

Common Application Fields of Aluminum Blister Foil

With its excellent properties and features, aluminum blister foil is widely used in many fields, especially in industries with high packaging requirements such as pharmaceuticals, food, and electronics.

Pharmaceutical Packaging Field

Pharmaceutical packaging is the primary application area for aluminum blister foil, accounting for over 70% of its total usage:

- Tablet and capsule packaging: widely used for packaging various solid dosage forms such as tablets, capsules, and pills.

- Cold forming packaging: used for high-end pharmaceutical blister packaging materials requiring high sealability.

- Tropical-type blister packaging: mainly used for pharmaceuticals in tropical areas or where high moisture protection is needed.

- Double aluminum packaging: uses composite materials to enclose tablets in the middle, offering excellent light protection.

- Bottle caps and sealing liners: aluminum foil is also used in pharmaceutical bottle caps and sealing liners to provide good sealing and anti-contamination protection.

| Application Field | PTP Aluminum Foil | Cold-Forming Aluminum Foil | Tropical Aluminum Foil | Pure Aluminum Foil |

| Pharmaceutical Packaging | Tablets, Capsules, Blister Packs | High-end Medicines, Sensitive Drugs | Medicines in Tropical Regions, IV Bottle Caps | General Pharmaceutical Packaging |

Food and Health Supplement Packaging

Food and health supplements are the second largest application area for aluminum blister foil, mainly due to its excellent protective properties:

- Premium Food Packaging: Aluminum blister foil is used for packaging chocolates, candies, nuts, etc., providing moisture, oxidation, and light protection.

- Ready-to-eat Food Packaging: Used in packaging for ready-to-eat and fast foods, providing good sealing and microwave adaptability.

- Health Supplement Packaging: Used for packaging vitamins and health products, protecting them from environmental influences and extending shelf life.

- Dairy Product Packaging: Used for packaging cheese, butter, etc., preventing oxidation and spoilage, while maintaining flavor and quality.

Electronics Packaging

The electronics industry has high packaging requirements, and aluminum blister foil is widely used in this field:

- Electronic Component Packaging: Used for packaging resistors, capacitors, integrated circuits, etc., offering anti-static, moisture-proof, and anti-oxidation protection.

- Battery Packaging: Used for packaging small batteries such as lithium and button cells, providing insulation and short-circuit protection.

- Precision Instrument Packaging: Used for packaging precision instruments and optical devices, offering shockproof, moisture-proof, and oxidation protection.

Aluminium Blister Foil Surface Treatments and Their Functions

To meet the needs of various applications, aluminium blister foil usually undergoes several types of surface treatments, including the following:

Degreasing Treatment: During rolling, aluminium foil retains residual rolling oil, which must be thoroughly removed. Food-grade and pharmaceutical-grade aluminium foils require especially stringent degreasing, typically through chemical or electrolytic degreasing processes, to ensure the surface is oil-free and to guarantee the adhesion of subsequent coatings and hygienic safety of the product. Clean degreasing is one of the key advantages of food-grade aluminium foil.

Coating Treatment: By applying various functional coatings to the aluminium foil surface, the printability, heat-sealability, and barrier properties can be enhanced. Common coating materials include:

Primer Layer: Usually composed of nitrocellulose, urea-formaldehyde resin, or acrylic resin, without plasticizers, applied at about 1.5g/m². This primer provides a good surface for subsequent printing and ensures firm ink adhesion.

Heat-Seal Layer: This is the key layer for sealing aluminium blister foil with plastic rigid sheets or another layer of aluminium foil, typically using specially formulated heat-seal coatings applied at 3.0-8.0g/m². The typical thickness of the heat-seal layer is around 5.6±0.5μm.

Barrier Coating: For certain special applications, high-barrier coatings such as silicon dioxide or aluminium oxide are used to further enhance the foil's resistance to gas and moisture.

Anodizing Treatment: Through electrochemical methods, a layer of aluminium oxide film is formed on the surface of the aluminium foil, improving its corrosion and wear resistance. By adjusting the anodizing process, surface roughness can be controlled to improve adhesion of printing and coatings. Anodizing usually includes degreasing, alkali cleaning, acid cleaning, anodizing, and sealing steps.

Surface Wettability Treatment: Chemical or physical methods are used to alter the surface wettability of the aluminium foil, increasing surface energy to ensure good adhesion of coatings and printing inks. O-temper aluminium foil should be oil-free, and the water brushing test result should reach Grade B or better.

Printing Treatment: Aluminium foil can undergo various printing processes, including gravure and flexographic printing. Pre-treatment is typically performed before printing to enhance ink adhesion. Printing provides essential functions such as product information, brand logos, and usage instructions.

Aluminium Blister Foil Production Process

Raw Material Preparation and Melting

The production of aluminium blister foil begins with the preparation and melting of raw materials. Suitable aluminium ingots and alloying elements are selected based on product requirements and melted in a furnace at 730-735°C. During melting, grain refining, degassing, slag removal, and chemical composition adjustments are performed.

Rolling and Annealing Process

The cast slabs undergo rough rolling, intermediate annealing, finish rolling, and final annealing to gradually reduce thickness and improve material properties. Intermediate annealing eliminates work hardening and improves ductility; final annealing adjusts the material's temper to achieve the desired hardness and strength.

Foil Rolling and Surface Treatment

A four-high irreversible foil rolling mill is used to reduce aluminium plates from approximately 0.3mm to foil thickness. During foil rolling, careful control of passes, tension, rolling oil, and flatness is required. Depending on the application, the foil then undergoes treatments such as degreasing, coating, anodizing, and surface wetting.

Slitting, Inspection, and Packaging

Slitting machines cut wide rolls into the desired width and roll diameter. The slit foil undergoes comprehensive quality inspection, including thickness measurement, pinhole detection, mechanical property testing, and surface quality checks. Final packaging ensures the product remains undamaged during transport and storage.

Aluminium Blister Foil Production Techniques and Key Technical Points

| Category | Details |

| Substrate Selection | Main alloy series: 8xxx series: |

| 8021-O | |

| 8079-O | |

| 8011-O | |

| Key control parameters: | |

| Forming Dome Height | |

| Heat Seal Strength | |

| Forming Process | Thermoforming Blister: |

| Uses vacuum forming to mold plastic rigid films (e.g., PVC, PVDC, PP, etc.) | |

| Medication is filled after forming | |

| Aluminium foil is heat-sealed onto the formed blisters using sealing machines to create sealed packaging | |

| Cold Formed Foil: | |

| Aluminium foil is pressed with molds to form drug cavities | |

| Outer aluminium foil is laminated with the thermoformed blister for double protection | |

| Quality Inspection | Key inspection indicators: |

| Pinholes: High-barrier requirements demand extremely low pinhole rates | |

| Seal Strength: Ensures packaging integrity to prevent air or water leakage | |

| Barrier Property: Water vapor transmission rate ≤ 0.5g/m²·24h to prevent moisture from affecting drug stability |

Aluminium blister foil is indispensable in pharmaceutical packaging, balancing protection, usability, and regulatory compliance. Its diversity in alloy types, coatings, and design enables it to meet various industry needs and adapt to evolving safety and sustainability trends.

Aluminium blister foil is an essential part of modern pharmaceutical packaging, offering unparalleled protection and convenience. Its adaptability to various packaging formats and compliance with regulatory standards make it the preferred choice for ensuring the safety and efficacy of medications.

Common Issues with Aluminium Blister Foil

Common problems encountered during the production of aluminium blister foil

Pinhole Issues

Causes

- Raw material issues: Inclusions or gas channels present in the billet

- Roll issues: Rough or defective roll surface

- Rolling process issues: Excessive back tension

- Rolling oil issues: Unclean rolling oil

- Environmental issues: Poor external environment with high dust levels

Solutions

- Improve billet quality and enhance aluminum melt purification

- Optimize rolling process and reasonably control back tension

- Improve roll quality through regular inspection and replacement

- Strengthen rolling oil management with regular filtration and replacement

- Improve production environment to reduce dust and impurities

Slitting Issues

Causes

- Tension issues: Insufficient back tension during rolling

- Flatness issues: Improper flatness control of incoming material

- Roll profile issues: Improper roll profile control

- Double-layer rolling issues: Excessive or uneven drip oil in double-layer rolling

Solutions

- Adjust tension parameters and increase back tension

- Improve flatness control to ensure incoming material is level

- Optimize roll profile control and reasonably spray cooling lubricant

- Standardize roll grinding and strictly follow parameter requirements

- Control double-layer drip oil to ensure even distribution

Common Issues During Aluminium Blister Foil Usage

Poor Heat Sealing

Causes

- Improper heat sealing parameters: Inappropriate temperature, pressure, or time settings

- Heat seal layer quality issues: Poor coating quality or unstable performance

- Surface contamination: Oil, dust, or other contaminants on the heat-sealing surface

- Material compatibility issues: Incompatibility with the sealed material

Solutions

- Optimize heat sealing parameters according to material characteristics

- Improve coating quality by selecting materials with stable performance

- Clean surface thoroughly to ensure no contamination

- Choose suitable materials to ensure heat sealing compatibility

How to Choose the Right Aluminum Blister Foil

Choosing the right aluminum blister foil is critical to ensuring product quality, extending shelf life, and controlling packaging costs. Below are key factors and methods for selection.

Select Based on Application Needs

- Product Characteristics: Consider the characteristics of the packaged product, including physical state, chemical properties, and sensitivity.

- Storage Conditions: Consider the storage conditions such as temperature, humidity, and light exposure.

- Usage Method: Consider the method and frequency of use—whether multiple uses are required, whether easy-open design is needed, etc.

- Target Market: Consider the target market and consumer group—whether it is aimed at children, the elderly, or special groups.

Select Based on Material Characteristics

- Alloy Type: Choose a suitable alloy type according to the application, such as 8011, 8021, 8079, etc.

- Material Temper: Select the appropriate temper based on forming needs, such as O-temper (soft) or H18-temper (hard).

- Thickness: Choose the appropriate thickness based on required strength and flexibility.

- Surface Treatment: Select the right surface treatment based on printing and heat sealing requirements.

Select Based on Performance Requirements

- Barrier Performance: Choose aluminum foil with suitable barrier properties according to product sensitivity to oxygen, moisture, light, etc.

- Mechanical Performance: Choose foil with appropriate mechanical properties based on mechanical stress during packaging and transportation.

- Chemical Stability: Choose foil with appropriate chemical stability based on the product's chemical nature.

- Hygiene and Safety: For food, pharmaceuticals, and other products that come into direct contact with the human body, select foil that meets relevant hygiene and safety standards.

| Application Scenario | Recommended Aluminum Foil Type | Recommended Thickness | Key Property Requirements |

| General Pharmaceutical PTP Packaging | 8011-H18 Aluminum Foil | 0.016–0.04mm | Good Printability and Heat Sealing |

| High-end Cold Forming Pharmaceutical Packaging | 8021-O Aluminum Foil | 0.04–0.065mm | Ultra-high Barrier, Good Cold Formability |

| Pharmaceutical Packaging for Tropical Regions | Tropical Aluminum Foil (8021-O / 8079-O) | 0.04–0.075mm | Excellent Moisture Resistance and Barrier Properties |

| Food Blister Packaging | 8011 or Pure Aluminum Foil | 0.02–0.03mm | Non-toxic, Tasteless, Good Heat Sealability |

| Electronic Component Packaging | Hard Temper Aluminum Foil | 0.02–0.03mm | Good Rigidity and Puncture Resistance |