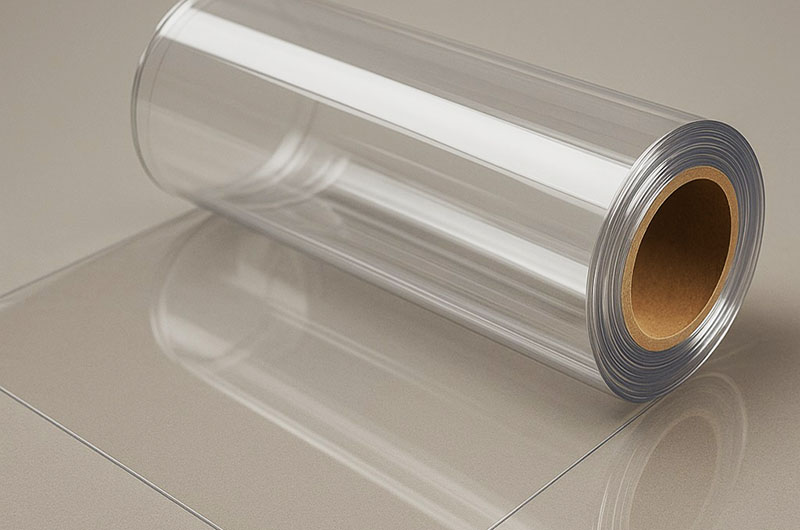

Clear PVC Film

Clear PVC film is a thin, transparent plastic sheet made from polyvinyl chloride. Its transparency results from a controlled polymer formulation and manufacturing process (typically calendaring or blown film extrusion), while its flexibility is achieved by adding plasticizers.

Clear PVC film is widely used, cost-effective, and features the following:

- High clarity and customizable thickness

- Durable barrier properties (waterproof, chemical-resistant, impact-resistant)

- Formable and printable surface

- Wide range of applications, from packaging to industrial uses

Clear PVC Film Properties

- Transparency: Crystal-clear visibility, ideal for window-type applications. Transparency varies with thickness.

- Thickness: Ranges from ultra-thin (approx. 0.05 mm) to semi-rigid (>0.5 mm), typically 0.1–0.5 mm. The thicker the film, the higher the strength.

- Durability and tear resistance: Strong, puncture-resistant, with high mechanical strength, suitable for long-term use.

- Waterproof and chemical resistance: Excellent barrier properties against water, oils, acids, alkalis, and other chemicals.

- Thermal performance: Softening temperature around 75–85°C; typically operates continuously at up to about 60°C.

- UV stability: UV inhibitors can be added to resist sunlight degradation and extend outdoor service life.

- Electrical insulation: High dielectric strength makes it suitable for electrical protection applications.

- Surface: Available in glossy, matte, textured, or printable finishes.

Clear PVC Film Composition and Manufacturing

Clear PVC film is a synthetic plastic polymer made from PVC resin, plasticizers, stabilizers, and additives. Its flexibility and clarity depend on the plasticizer content (PHR); the higher the PHR (e.g., 22–60 PHR), the softer the film. Two main production methods are used:

- Calendaring: Heated PVC is passed through rollers to form uniform, glossy sheets (used for thicker films >0.1 mm).

- Extrusion: Suitable for thinner films (0.025–0.5 mm) with precise thickness control. After production, the film is cooled and wound onto cores (e.g., 2–3 inch paper tubes), with anti-blocking agents such as corn starch applied to prevent sticking.

Clear PVC Film Types

| Transparency Grade | Description |

| Standard Clear PVC Film | Standard clear PVC film offers good optical clarity, clearly displaying contents. It is commonly used for bedding, stationery, clothing, and everyday consumer goods packaging. This film balances flexibility, strength, and cost, and is suitable for heat sealing, printing, and high-frequency processing—an ideal material for general-purpose packaging applications. |

| Super Clear / Crystal Clear PVC Film | Super clear or crystal clear PVC film undergoes special water filtration processing, resulting in a cleaner surface with fewer impurities and higher optical clarity. It allows nearly unobstructed viewing of underlying items (e.g., roll cores or product labels). This film is often used in high-end packaging, cosmetic sets, and gift box windows where product visibility is crucial. |

Clear PVC Film Variant Types

| Type | Description |

| Plasticized (Soft PVC) | Plasticized (Soft PVC) is a flexible PVC film with added plasticizers, providing excellent softness and extensibility. It is suitable for applications requiring bending or surface conformity. This material is widely used in shower curtains, flexible packaging film, tablecloths, raincoats, and medical tubing. It is soft to the touch, highly transparent, and easily heat-sealed—an ideal representative of flexible transparent films. |

| Unplasticized (Rigid PVC) | Unplasticized (Rigid PVC) is a hard PVC film without plasticizers. It has high rigidity, impact resistance, and dimensional stability. This material is commonly used in transparent clamshells (such as for electronics), signage, display boards, and structural applications like window frames, particularly where shape and structural strength must be maintained. |

| Semi-Rigid PVC | Semi-Rigid PVC is an intermediate type between soft and rigid, retaining some flexibility while offering moderate structural strength. It is suitable for thermoforming and forming into complex shapes. It is widely used in automotive interior panels, tool trays, and food packaging boxes where slight bending is needed without losing form—making it a versatile packaging material option. |

Clear PVC Film Physical Properties

- Thickness range: 0.025 mm – 3.0 mm.

- Width: Up to 2.4 meters; customizable range: 40 cm – 200 cm.

- Temperature resistance: -40°C to +75°C (Vicat softening point).

- UV resistance: Optional additives can prevent yellowing and degradation outdoors.

- Flame retardancy: Complies with public safety standards such as DIN 4102 (B2/M2).

Performance Specifications (Sample from DuraTarps DLT-7004 film)

| Spec | Typical Value |

| Thickness | 0.4 mm (max width 2.4 m) |

| Tensile Strength | ≥210–250 kg/cm² |

| Elongation | ≥170–260% |

| Tear Strength | ≥5–9 kg/mm |

| Vicat Softening | ~75 °C |

| Certifications | REACH/RoHS, UV, Cold, Anti-Stat, Fire-Retardant |

Features include UV/chemical resistance, self-extinguishing, waterproof, stable dimensions

Comparison of Clear PVC Film Types

| Type | Key Features | Common Applications |

| Super Clear | Water-filtered, >90% transparency, sticky surface | High-end packaging, display windows |

| Fire Retardant | Self-extinguishing, B2/M2 certified | Public tents, event halls |

| Adhesive-Coated | Permanent adhesive backing, 3H hardness | Decals, industrial labels |

| Anti-Static | Conductivity for electronic environments | IT labs, cleanrooms |

Clear PVC Film Industry Applications

Common Applications

Packaging and Retail: Blister packaging, clamshell packaging, food/pharmaceutical packaging, protective sleeves.

Windows and Enclosures: Greenhouse walls, boat/golf cart windshields, patio curtains.

Protective Covers: Furniture covers, machine guards, cleanroom partitions.

Medical and Cleanroom: IV/disinfection bags, medical-grade packaging.

Signage and Graphics: Printable film for window graphics, overlays, display racks.

Industrial Uses: Wire insulation, chemical-resistant linings, thermoforming prototypes.

| Application Field | Specific Uses | Thickness Range (if applicable) |

| Packaging | Bedding packaging, cosmetic bag packaging, stationery packaging | — |

| Construction | Tent windows, canopy covers, skylight construction films | 200–1000 microns |

| Strip curtains for industrial door seals, providing thermal/sound insulation | 2–3 mm | |

| Consumer Goods | Tablecloths, shower curtains, inflatable toys | — |

| Scratch-resistant protective film for electronics | 0.1–0.3 mm | |

| Medical/Industrial | Urine bags, relief bags, chemical-resistant barriers | — |

Clear PVC Film Technical Specifications

Performance Indicators:

- Tensile Strength: 170–280 kg/cm² (varies with PHR).

- Elongation: Up to 280% for highly flexible applications.

- Dimensional Stability: Shrinkage ≤5% (thickness 0.255–0.50 mm).

Certifications:

- Complies with REACH/RoHS standards for the EU market.

- Phthalate-free, certified under EN71-3 (toy safety) and CONEG.

Thickness vs. Application Guidance

|

Thickness |

Ideal Applications | Performance Traits |

| 0.025–0.1mm | Light packaging (e.g., document sleeves) | Flexible, low-cost |

| 0.2–0.4mm | Social distancing screens, stationery bags | Balance of clarity and durability |

| 0.5–1.0mm | Industrial curtains, marine windows | Weather/UV resistant |

| >1.0mm | Strip doors, heavy-duty covers | High tear strength |

Clear PVC Film Surface Finishes

- Double Polished: High gloss (e.g., for menu covers).

- Matte/Orange Peel: Anti-glare or scratch-resistant.

- Color Options: Clear, blue, green, smoke; tint affects light transmittance.

Clear PVC Film Outdoor Longevity

For outdoor use, choose films with UV stabilizers—typically lasting 3–5 years, like 16‑mil greenhouse-grade films rated for ~4 years.

Clear PVC film is a versatile thermoplastic that combines optical clarity, mechanical toughness, and chemical stability. Its application ranges from simple packaging to critical architectural solutions, thanks to customizable thickness, plasticizer levels (PHR), and specialty additives. Innovation focuses on environmental compliance and multifunctionality (e.g., UV resistance + flame retardancy), ensuring its role in sustainable packaging and smart building sectors. When selecting the film, priority should be given to thickness for structural needs, surface treatment for appearance, and certifications for regulatory compliance.